Introduction to 3-Phase vs. Single-Phase Generators

Understanding Basic Power Generation Systems

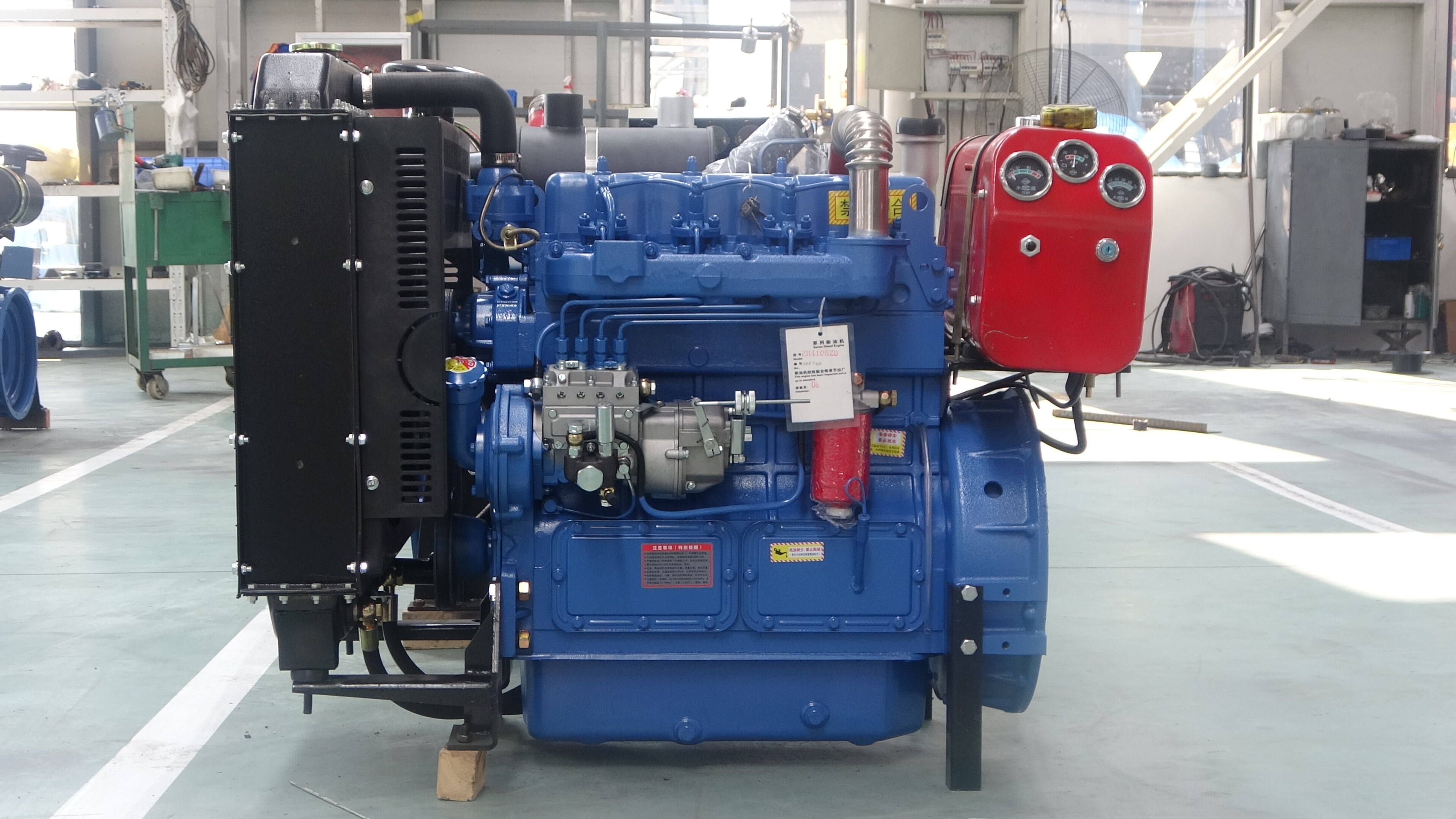

Power generation systems are pivotal for sustaining operations across diverse settings, from households to industrial facilities. At the core, power generation involves converting mechanical energy into electrical energy to fulfill the power needs of various equipment. There are primarily two types of systems: 3-phase and single-phase generators. Single-phase systems transmit power through a single sine wave, ideal for residential and light-duty applications. Conversely, 3-phase systems utilize three sine waves offset by 120 degrees, providing robust power suitable for industrial and heavy-duty uses. These systems vary based on load requirements; where single-phase suits lower power needs, 3-phase accommodates high-demand settings due to its ability to maintain consistent power output, integral to running large machines efficiently.

Key Differences in Design and Functionality

When it comes to design and functionality, 3-phase and single-phase generators exhibit distinct features that influence their performance. A 3-phase generator has three conductor wires and a neutral wire, which work in tandem to ensure balanced power delivery, minimizing voltage fluctuations. This design enables it to deliver energy continuously, making it optimal for large-scale equipment. Single-phase generators, meanwhile, incorporate fewer conductive wires, typically two, resulting in a less steady power supply. Functionality varies as well; 3-phase generators distribute load effectively across three phases, enhancing efficiency and reliability. Their higher voltage levels and stable frequency output make them suited for heavy-duty operations, whereas single-phase generators are more susceptible to power disruptions, suitable for smaller applications.

Importance of Selecting the Right Generator Type

Selecting between 3-phase and single-phase generators is crucial for matching the generator type to application needs. Choosing the wrong generator can lead to inefficiencies and operational challenges. For instance, using a single-phase generator in high-demand environments may result in inadequate power supply, whereas employing a 3-phase generator for basic functions could mean unnecessary expenditure. Statistics indicate a misapplication can increase energy costs by up to 25%. Experts emphasize assessing power requirements before making a decision. Understanding load types, voltage demands, and operational context can help prevent such pitfalls, ensuring optimal performance and cost-effectiveness. The right generator type not only supports daily operations but also sustains productivity, preventing costly energy failures.

Higher Efficiency and Power Output of 3-Phase Generators

Continuous and Balanced Power Delivery

3-phase generators offer significant advantages in maintaining a continuous and balanced power supply, effectively minimizing downtime. These systems are designed to deliver power steadily across multiple phases, ensuring that equipment operates smoothly without interruptions. A balanced load distribution across the phases contributes to the prolonged lifespan of electrical devices, as it reduces the stress and wear on individual components and avoids overheating issues. A study published in Electrical Engineering Journal reveals that 3-phase systems exhibit up to 30% better efficiency in power delivery compared to single-phase systems, providing a robust performance that is ideal for industrial applications (3-phase generator).

Reduced Energy Losses Compared to Single-Phase Systems

3-phase systems are superior in minimizing energy losses, which in turn lowers operational costs. Unlike single-phase systems, where energy is more likely to dissipate due to uneven voltage and current flow, 3-phase generators utilize improved electrical characteristics that support higher efficiency levels. This results in less wasted energy, thereby translating into financial savings for businesses in the long run. According to a report from Electric Power Research Institute, the energy efficiency rates of 3-phase systems can be as much as 20% higher, indicating a substantial advantage in performance and cost-effectiveness (3-phase generator).

1.5x Power Factor Advantage

Understanding the concept of power factor is crucial to appreciating generator efficiency. Power factor is the measure of how effectively electrical power is converted into useful work output, and 3-phase generators possess a distinctive power factor advantage. With a power factor up to 1.5 times higher than that of single-phase systems, 3-phase generators ensure more efficient utilization of the electricity supplied. This efficiency is highlighted in case studies where industries experienced enhanced operational capabilities due to better power factor management, as detailed in a comprehensive analysis by Modern Energy Solutions (3-phase generator). Such advantages make 3-phase generators indispensable, especially for applications demanding uninterrupted high power and robust efficiency.

Superior Performance in Heavy-Duty Applications

Handling Industrial Machinery and Large Motors

3-phase generators are specifically engineered to support high-powered industrial machinery and large motors, offering seamless performance for heavy-duty applications. These generators provide the high starting torque required for large motors used in industrial settings, ensuring that machinery runs smoothly without interruptions. According to industry experts, the reliability of 3-phase generators significantly reduces the risk of system failure in demanding environments. Statistics from a recent study underscore this advantage, highlighting a lower failure rate in facilities that utilize these robust power solutions for their operations.

Optimal Performance for Commercial Infrastructure

In commercial settings, the reliability and efficiency of 3-phase generators make them an attractive choice. Businesses can achieve superior performance and energy reliability by integrating these generators into their infrastructures. Case studies, for instance, have demonstrated how companies using 3-phase systems have improved their operational efficiency and managed power disruptions more effectively. Advanced 3-phase technologies are increasingly being adopted in modern commercial designs to ensure uninterrupted power supply, aligning with the growing complexity of commercial infrastructure demands.

Scalability for Growing Power Demands

The scalability of 3-phase generators is a crucial advantage for businesses anticipating growth in power demands. These systems can be incrementally scaled to support increasing loads, ensuring consistent energy supply without compromising efficiency. The modular nature of 3-phase generators allows for adjustments that enhance energy efficiency as demands grow. According to industry forecasts, sectors relying heavily on these generators are expected to see a significant rise in power requirements. For instance, data centers and manufacturing plants are projected to experience a surge in power consumption in the coming years, further emphasizing the need for adaptable solutions like 3-phase generators.

Enhanced Voltage Stability and Operational Reliability

Less Fluctuation in Voltage Supply

Voltage stability is a critical aspect of power generation systems, influencing both operational efficiency and the longevity of connected devices. In the context of three-phase systems, voltage stability refers to the system's ability to maintain consistent voltage levels despite changes in load or other external factors. Compared to single-phase generators, three-phase systems maintain a more balanced voltage output. This is due to the unique configuration of three-phase generators, which generate power through three windings at a constant 120-degree phase difference. This results in a steady and continuous power flow, reducing voltage fluctuations. Technical specifications reveal that three-phase generators often exhibit superior voltage regulation, making them well-suited for applications requiring stable power output.

Reduced Risk of Power Interruptions and Equipment Damage

The reliability of power supply significantly impacts the operational lifespan and performance of equipment, particularly in mission-critical applications. Three-phase generators offer enhanced operational reliability by providing a stable power output, thus minimizing the risk of power interruptions that could lead to equipment damage. This stability is crucial for environments like data centers and manufacturing units where any power disruption could incur substantial costs. There are numerous documented case studies demonstrating the effectiveness of implementing three-phase systems in improving infrastructure reliability. In many instances, facilities that transitioned to three-phase generators experienced a marked reduction in equipment failure rates, illustrating the tangible benefits of this technology in safeguarding valuable assets from power instability and related damages.

Conclusion

Ideal applications for 3-Phase Generators

3-phase generators are ideally suited for industries requiring robust power systems and efficient electrical distribution. They are particularly beneficial in applications such as data centers, manufacturing plants, and construction sites where high power demand is continuous and critical. For example, industries like aviation and telecommunications frequently utilize these systems due to their reliable power output and ability to handle large loads efficiently. The adaptability of 3-phase technology also makes it ideal for environments with fluctuating power needs, ensuring consistent operational performance across various sectors.

Key considerations when selecting the right generator

When choosing the appropriate generator type, several key factors must be evaluated to ensure an optimal match to your needs. Firstly, consider your power requirements, which will dictate the size and capacity of the generator needed. Efficiency metrics are also crucial to ensure cost-effectiveness and sustainable operation over time. Furthermore, the specific application and environment where the generator will be used should guide your choice, whether it involves industrial, commercial, or residential applications. Consulting with industry experts is essential to improve decision-making, enabling you to select a generator system that delivers reliability and meets your specific operational demands.

FAQ

What are the main differences between single-phase and 3-phase generators?

Single-phase generators utilize one wave to transmit power and are ideal for residential and smaller applications, whereas 3-phase generators use three waves, offering a more consistent power output suitable for industrial uses.

Which type of generator is more efficient?

3-phase generators are generally more efficient, offering better power factor and reduced energy losses, which makes them suitable for heavy-duty and industrial applications.

Are 3-phase generators more cost-effective in the long run?

Yes, they often result in lower operational costs due to reduced maintenance needs and more efficient fuel consumption.

What factors should I consider when choosing a generator?

Consider your power needs, efficiency requirements, and the environment where the generator will be used. Consulting with industry experts can help in making the best choice for your specific needs.